Last time I had spent lots of time repairing, preparing and painting the body panels, which the majority of them are now located in a spare room in the house….

This time, it;s all about taking another look at the Front Axle. If you read previous articles, you will know that the half shaft on the Near side front would not go in properly, without effort, and even when it was in it became stiff. Clearly that is not right. So I took another look.

First thing was to take it off Isobel, and strip it down.

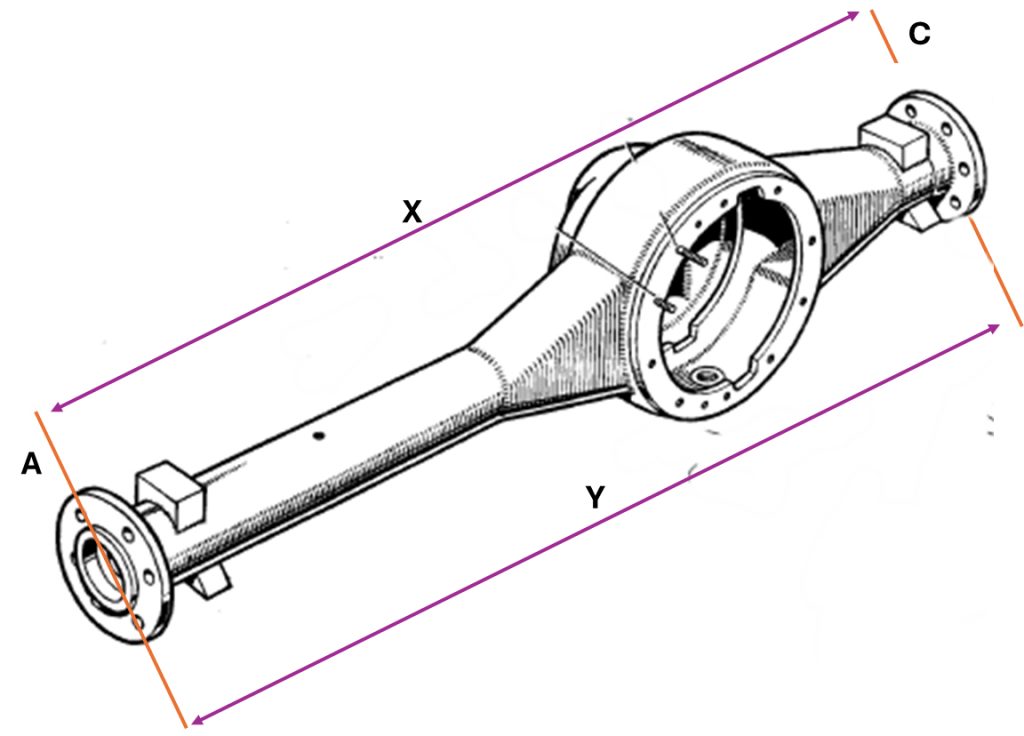

I then need to work out if is actually twisted or bent. So, bolted 2 pieces of wood, exactly the same length to each end (A & C (not sure what happend to B?). I then measured X and Y, in theory they should be the same.

But they were not, they were out by 5/10mm depending on which holes I bolted the battens to. So the conclusion is that the front Axle case is actually bent. Back to the Series 2 club trading place on the forum. “Anyone got a Series 2A front axle case for the 1965 SWB?” Again, it came up trumps, in-fact 2 people came back to me. The second one, didn’t actually have one, but will in a week or 2, so I reserved that one, but at the same time spoke to the first chap and we agreed a price and pickup. (my nephew and his wife were actually visiting family, about a mile away from where this guy was, so they kindly picked it up for me).

Got he Axle back, and tried the Diff, Swivels and importantly the Half shafts, and voila, it all went together perfectly. Only issue was it was for an earlier vehicle, and pretty sure for a 109, but it would work. Just as I was planning to clean it up and paint it, the other chap came back to me “I’ve got one now, and it looks in really good condition, and is the right age and one for my vehicle. So I arranged to go get that one as well. Just so happens, he is the Chairman of the Series 2 Club, which inevitably lead to a long conversation.

So in an attempt to keep this short, Cleaned it up a little (was pretty good anyway), and got it onto Isobel.

This time, rather than doing temporary fix’es of all the bits, did them all properly, Checked the swivels, wheel hub bearings, fitted the brake cylinder and torqued everything up. Including the Springs, which also allowed me to fit the shock absorbers.

Tightening the road springs is not just a case of tightening the bolts, they need to be set to a certain distance from the chassis.

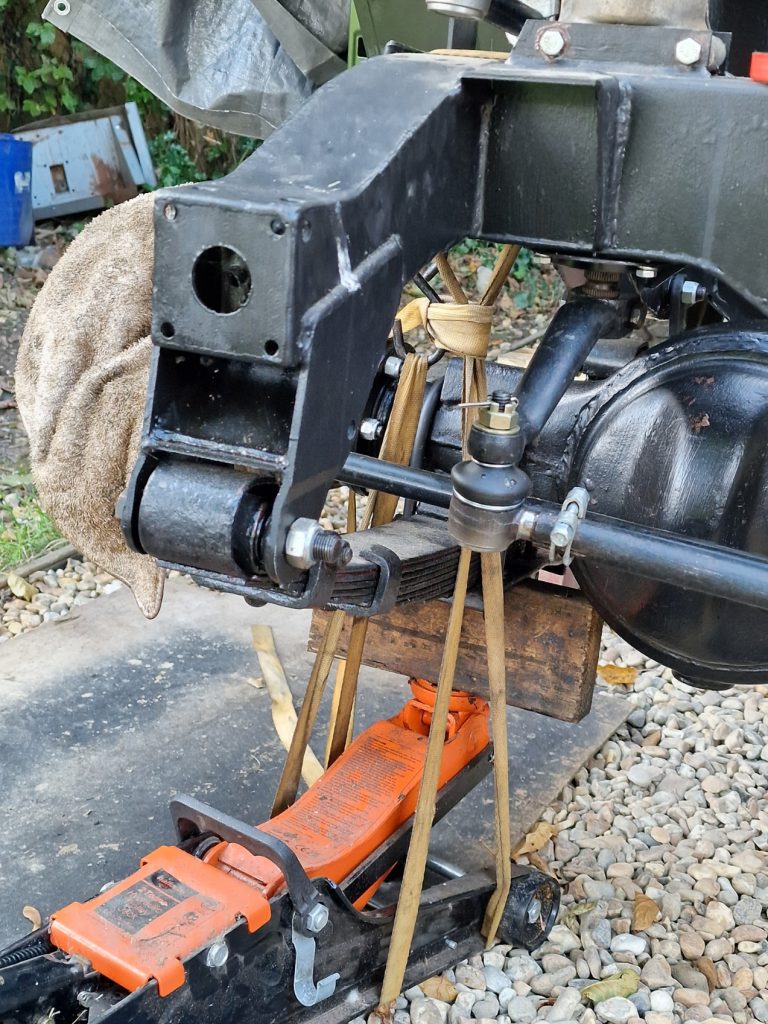

So, with a trolley jack, straps over the chassis, compressed the springs to the right distance before torqueing the bolts up.

Did this on all 4 corners, so the rear was also done at the same time.

finally, and this will test my work, added some oil and grease to the Swivels (One Shot, which is a little thicker than oil, and should help stop oil leaks), and 1.75 Litres of EP 90 in each of the Diffs.

Will check back in a week or so to see if I have any leaks!

So thats the axles all done, finally… Oh, except for one thing, the U-bolt nuts. Which need to be torqued to about 60 lb ft. Did one, and it stripped the thread…. Not too worried, will get a replacement and tighten them over time as the UBolts do (apparently) stretch over time.

While all of this was going on, also got on with a few other bits and pieces. Need to clear the decks of outstanding jobs before starting on the next part.

Seatbox tool tray / battery box. This was rotten, well parts of it, so decided to take the angle grinder to it to cut out the rot. I originally planned to make a new one, but bending steel, even mild steel is not so easy, to get nice straight bends.

But, they do say it’s who you know not what you know. During a small get together at my brother In-laws, was chatting to his brother in-law who has an interest in cars, and showed him Isobel. Just happened to mention my plans for the Seat box tray, at which point he said, I’ve got a bender, you can have it if you would like! Ummm, Yes please, so exchanged it for a nice bottle of red. I cut out the shapes, and set about making replacement parts for the rotten bits.

Not too bad for yet another first, metal fabrication. Off they went to my Nephew Lee, who by the way has just gone out on his own as a Mobile Mechanic, LG Mobile Autos to be welded into whats left of the original box.

Also thought I would paint a few bits that have been sitting around for a while, Battery tray, Handbrake mechanism & Fuel tank. Also set about another tidy up of the workshop.

Nearly forgot, on the front axle, and other places there are a few exposed metal bits not painted. While I have been busy with other stuff, they had started to develop some surface rust. Not a good look, so cleaned them up and sprayed them with a clear, gloss, etch lacquer. Be interesting to see how they fair over the coming weeks.

So thats it for another article, Will be finishing off some of the bits that still need finishing, like fitting the supports to the underside of the rear tub, trying to put in some solid domed rivets on the bonnet to secure the bonnet frame and take another look at the foot pedals, which need a bit of work.

But, the more exciting part will be a new shopping list to allow me to move to the next stage. This will include all of the brake pipes and fittings and also a new wiring loom or rather looms. Both of which need to get done before the rear tub can be put back on the chassis for good.

Again, hope you enjoyed the read, bit all over the place this time, but edging closer and closer to the next big jobs, Gearbox & Transfer box and the Engine.

Leave a Reply