Straight back to it then. Started the day off by checking the torque on the Main Bearing caps (85lb ft) and Piston Connecting rods (Big ends), supprisingly low torque (25 lb ft).

The goal for tody, was to get a few ancillary parts onto the engine.

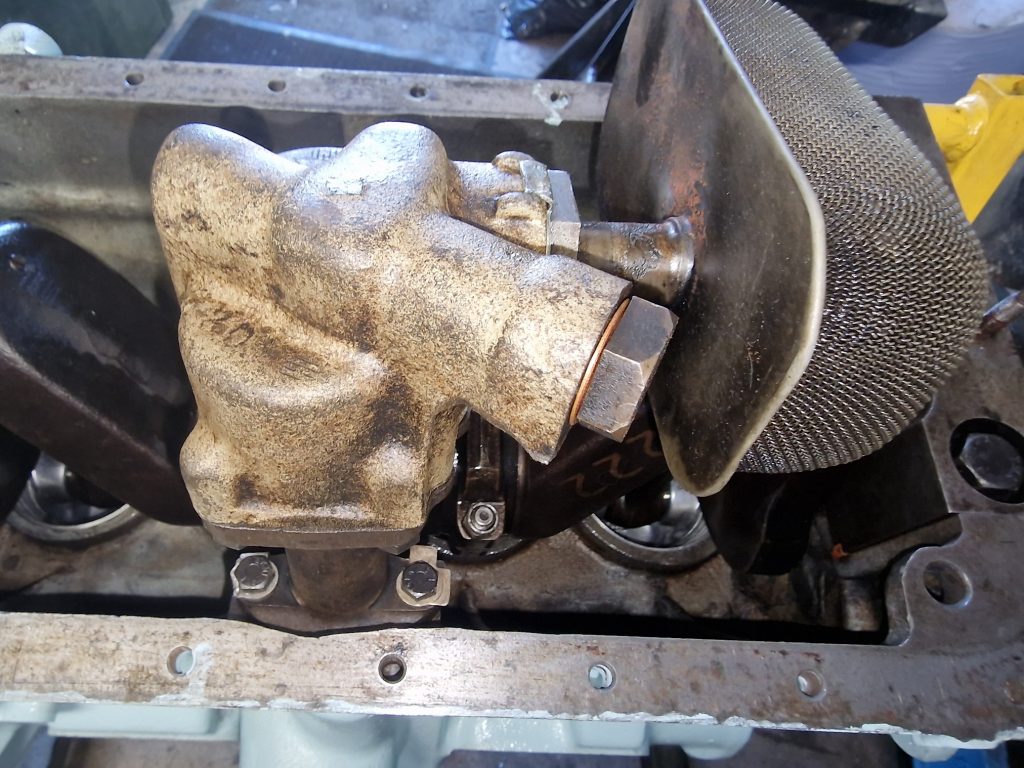

First, was the Oil Pump, this needs to go in before the suimp goes on. No pictures of my stupid error!

The filter part (to the right), I put it on facing the wrong way! Stupid mistake, so had to ease out the locking tab, undo the nut, move it and re-tighten it all back up.

I hav’nt checked that the pump actually works, although did check it out and it looked fine, wrote about that here, so will have to keep a close eye on oil pressure when I do start the engine for the first time.

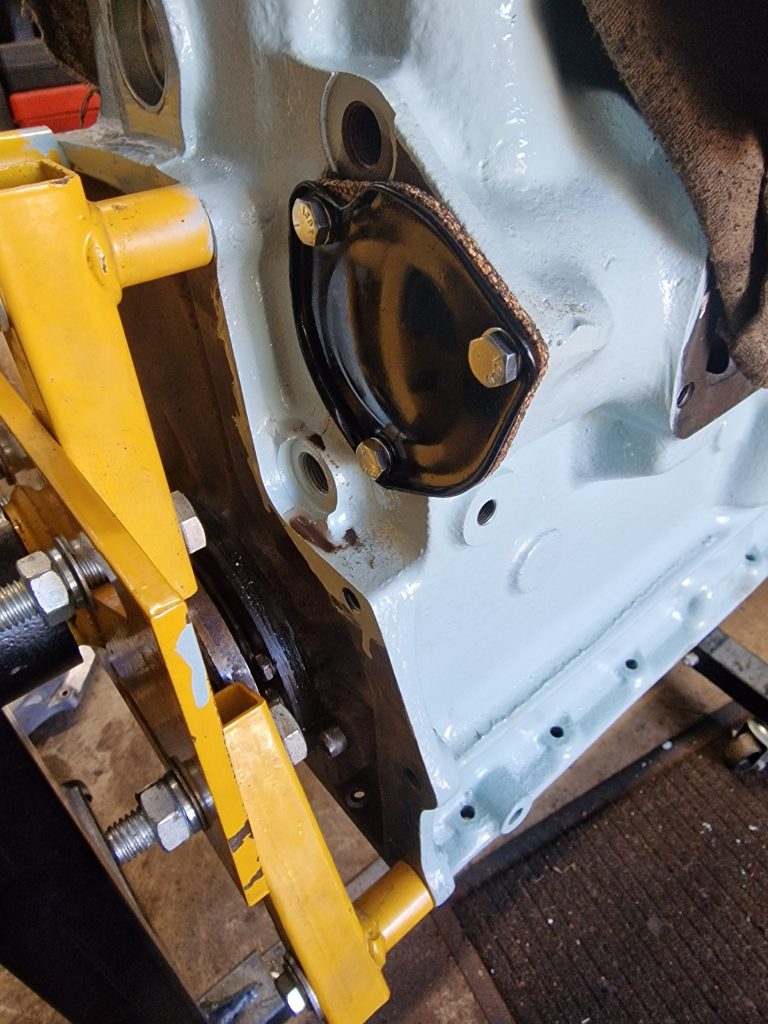

Next was to put the front cover on. This took me an age to figure out the bolt sizes for each of the holes, there are 4 different sizes, mostly 5/16 U.N.F., but on the water pump, which I test fitted that at the same time, there are some 1/4″ U.N.F. and two I could’nt figure out. Turns out they are 1/4″ U.N.C., which is a little odd, as it didnt change to U.N.C. untiul after the suffux on my engine, mines a Suffix G, and it changed to UNC from suffix H, hey ho, need to but 1 bolt for that 🙁

Just for info, UNF means United National Fine (Fine being the thread pitch) and UNC United National Course, again course being the thread pitch.

Before I went ahead and put gasket seal on the gaskets, and try to bolt it on, I re-tapped all of the holes in the engine block to make sure it bolted up nicely.

I also re-tapped the holes for the rear cam shaft cover, which was duely fitted with a dry cork gasket. Hope thats right, it was the only gasket in the gasket set that was the right shape.

Front cover on, and all new BZP (Bright Zinc Plated) bolts and spring washers.

Continued at the front and bolted the water Pump on. I was going to service the old pump, but broke it while trying to take it apart, so bought a brand spanking new one some time ago, looks good.

If you look carefully in the background, you can see some new (to me) shelves, with all (most) of the engine parts ready to be fitted.

Turned the engine upside down again, for the last time hopefully, and put the sump on.

Something like 21 bolts and 1 Nut that needed gently tightening all the way around so as to not distort the sump, which is a relativly thin material, so could easily buckle.

Finished the day with a test fit of the engine mounting brackets.

Need to get some new bolts for these, so these will come off again later.

Need to check I have these on the right sides.

So what next, well thats a good question. I could continue adding parts to the engine, The Head, Fuel Pump, Distributor, Oil Filler, Oil level stick and some other bits, but have decided to stop there for now, as I think I will put it into the chassis before adding some of those parts, will make the lift and moving it a little easier.

I planned to hire an engine hoist, but cant be sure I will get it all done in the time I have it for, so bitten the bullet and ordered myself one, a relativly cheap one, and once i’m done with it can sell it on.

Also, this will allow me some time to place yet another order for things like clutch, some more bolts, some special bolts for the fly wheel. when i’ve got them all, I can then put the gearbox and engine in, in one go, apparently thats easier than doing them seperatly.

Only down side is that he bulkhead will have to come off. Not too much of a big deal, will have an engine hoist in a couple of days to lift it off.

So what will i spend my time doing, well, I might finish off some of the body work, still have the dynamo to service, might start bolting engine mounts onto the chassis, might put the handbrake mechanisum on, who knows, but what ever I do, I will write about it here.

Leave a Reply