Its been a while since the last update, and thats for a number of reasons. Had to have a small operation, repair our swimming pool and take down a shed in the garden, due to rodents.

Anyway, back at it again now and while all of that was going on, not been entirely inactive.

In the last update, I had stripped down the engine, and was thinking about what needed to be done.

After a personal recommendation, and reading a number of superb reviews decided to give Banda Engineering a call. Banda Engineering are based in Portsmouth, right near the Navel Base main entrance which I knew well after all the times I dropped and picked up my eldest son when he went on or came back from deployments.

After a brief call, took all the engine bits down, not really knowing what exactly needed to be done. After 5 minutes of Banda taking a look, a couple of measurements later and telling me exactly what needed to be done I was more than happy.

So what was done?

The pistons that came out were original, so possibly could have gone with 020 oversize.

As it turned out, the block was cleaned up a little and re-bored to 030.

Number 4 had a bit of a score mark, probably the reason for skipping 020.

So re-bored and honed, ready for new Pistons.

Next, the head. This was again cleaned up, painted and skimmed with hardened valve seats fitted and existing valves re-ground in.

Also, there was a couple of snapped bolts from the manifolds, these were taken out also.

The crank shaft was measured and shown to be in tolerance, so was treated to a polish of the journals.

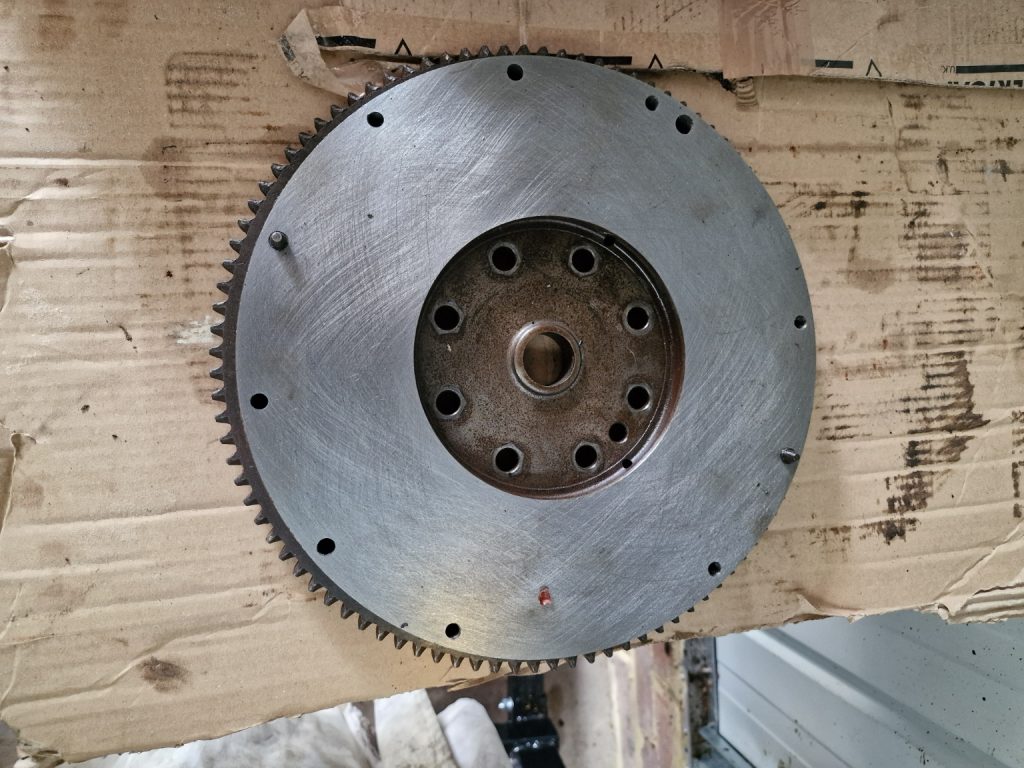

Last up was the flywheel, to me it looked beyond saving, however, this was re-skimmed back to as good as new.

Now I’m a little new to this level of detail so cant really judge the quality of work, but from what I see, the price I paid I’m super happy it all looks great and Banda, while being more used to working with people who know what the hell they are on about were super helpful.

This is when things stopped for a while, except me stocking up my store cupboard with a few new parts, ready to re-start the re-build.

What did I buy? other than some Assembly lube, some other lubricants and sealers along with some more WD40, scotch bright pads and some squirty bottles.

Most of what I bought came from Turner Engineering as I didn’t want blue box (Britpart) parts In my engine, same as when I have done all other major parts so far.

- Oversize Pistons (0.03)

- Main bearings (Standard size)

- Thrust washer for crank shaft. (Standard size)

- Connecting Rod bearings (Standard Size)

- Top end gasket set

- Bottom end gasket set

- Oil seal for rear of Crankshaft

- Timing chain

- Various lock tabs

All of this “should” be enough to complete the main engine rebuild.

Getting ready for the build, I need to do some more cleaning, mostly ready to paint the block but also so I am working with completely clean engine parts, essential as I understand.

First thing is to mask up the block, making sure the insides keep as clean as possible and free from paint.

A little tip I saw somewhere is to put the masking take on, and then gently with a small hammer, tap the edge, which creates a really nice, clean edge.

Will come back soon, after I get the casings all cleaned up and painted and also when I start putting things back together.

Leave a Reply